C-TECH是一家领先的制造和开发公司,自1997年成立以来,主要研发生产销售SAW滤波器业务,至今已超过20年。C-TECH采用优异的原料,先进的技术设备生产,产品品质和经验丝毫不输同行。C-TECH晶振正在开发一种半导体工艺,可以独立完成制造和组装。凭借积累的技术和知识,我们提供定制开发根据客户要求的规格。

基于ISO 9001和ISO 14001的可靠性,声表面波滤波器开发和生产本身就是生产CDMA / LTE / 5G移动中继、国防工业、基站、收音机、无线寻呼机、无线麦克风、调频、DMB、GPS、WiFi、高通、蓝牙、IOT等正在被应用到无线业务的各个领域。下面C-TECH对自己精心钻研的产品SAWFILTER声表面滤波器进行详细介绍。

声表面波滤波器(表面声波)是使用表面声波控制信号频率分量和相位分量,以消除相邻信道信号,它是一个带通滤波器(BPF),对接收信道信号进行整形。

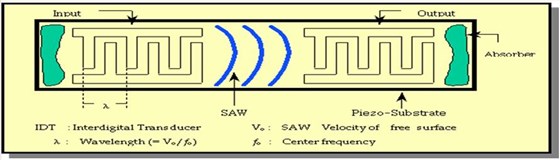

SAW滤波器的工作原理

当梳状电极(IDT)形成在压电基板的两侧并且电信号施加到输入端时,沿衬底表面传播的表面声波(SAW)由压电效应产生,并在输出端转换回电信号。这些SAW器件的频率特性由IDT电极的几何结构决定。

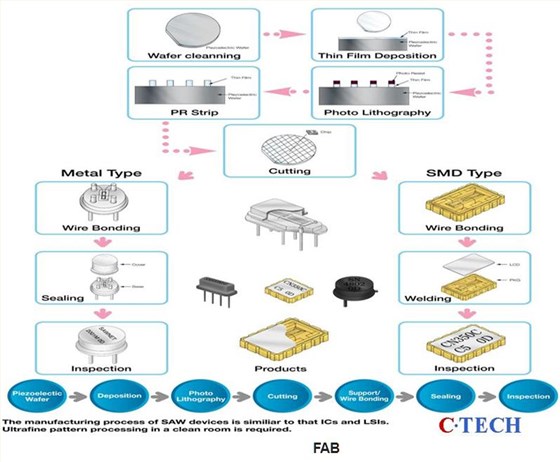

SAW滤波器制造工艺

| Process | Equipment | Description |

|---|---|---|

| WAFER Cleaning | Wet Station Rinse & Drier | Process to remove foreign substances causing short circuit defects on the wafer surface before AI deposition and to increase adhesion between the wafer surface and AL |

| Sputtering | Sputter T/Profiler | Process for depositing AL on wafer surface to desired height |

| P.R Coating | Coater | Process for applying photo Resist on AL |

| Exposing | Aligner Stepper | First step process of pattern formation by irradiating UV on PR through MASK |

| Developing | Developer Scope | Process of removing UV irradiated PR for AL Etching after Exposing |

| Etching | Wet Station Rinse & Drier | Process of implementing the final pattern by removing the AL in each selected manner |

| Stripping | Wet Station Rinse & Drier | Process for removing PR that protects AL patterns |

| Auto Probing | Auto Prober Dry Oven | Process for determining good and bad products by measuring metod before puttiong the products divided into cells of the wafer into assembly |

Assembl

| Process | Equipment | Description |

|---|---|---|

| Absorber Coating | Screen Printer Dry Oven | Process of applying an absorber to each cell to improve the characteristics of the output to the measuring device |

| Dicing | Tape Mounter Dicing SAW Cleaner | Process of cutting each cell of the wafer based on the Dicing Line |

| Die Bonding | Die bonder Epoxy Dispenser UV,Dry Oven | Process of bonding base and chip by applying epoxy |

| Wire Bonding | Wire Bonder | The Process of connecting the terminal of the BASE and the PAD of the CHIP to transmit an electrical signal to the AL wire |

| Can Sealing | Spot Welder Seam Sealer Dry Oven | Welding Process using Lid & Cap to protect the chip |

| Marking | Laser Maker | Process of laser marking the product’s unique model name and data code |

| Testing | Network Analyzer | Process for final inspection of product defects |

| Q.C | Network Analyzer | Process of sampling and inspection of mixed or defective products |

| Packing | Tape & Reel | Q.C process for packaging completed products |

| Shipping | Shipment of all process and packaged products |

SMI晶振,86M0368 -16,86SMX进口晶振,6G相关设备晶振

SMI晶振,86M0368 -16,86SMX进口晶振,6G相关设备晶振 日本SMI晶体,53SMX石英晶振,53M320-16,6G基站晶振

日本SMI晶体,53SMX石英晶振,53M320-16,6G基站晶振